RIVETING STATION FOR AUTOMOTIVE INDUSTRY

Client: AS Norma (part of Autoliv group)

Project Completion Date: August 30, 2023

Application: Industrial Riveting Workstation

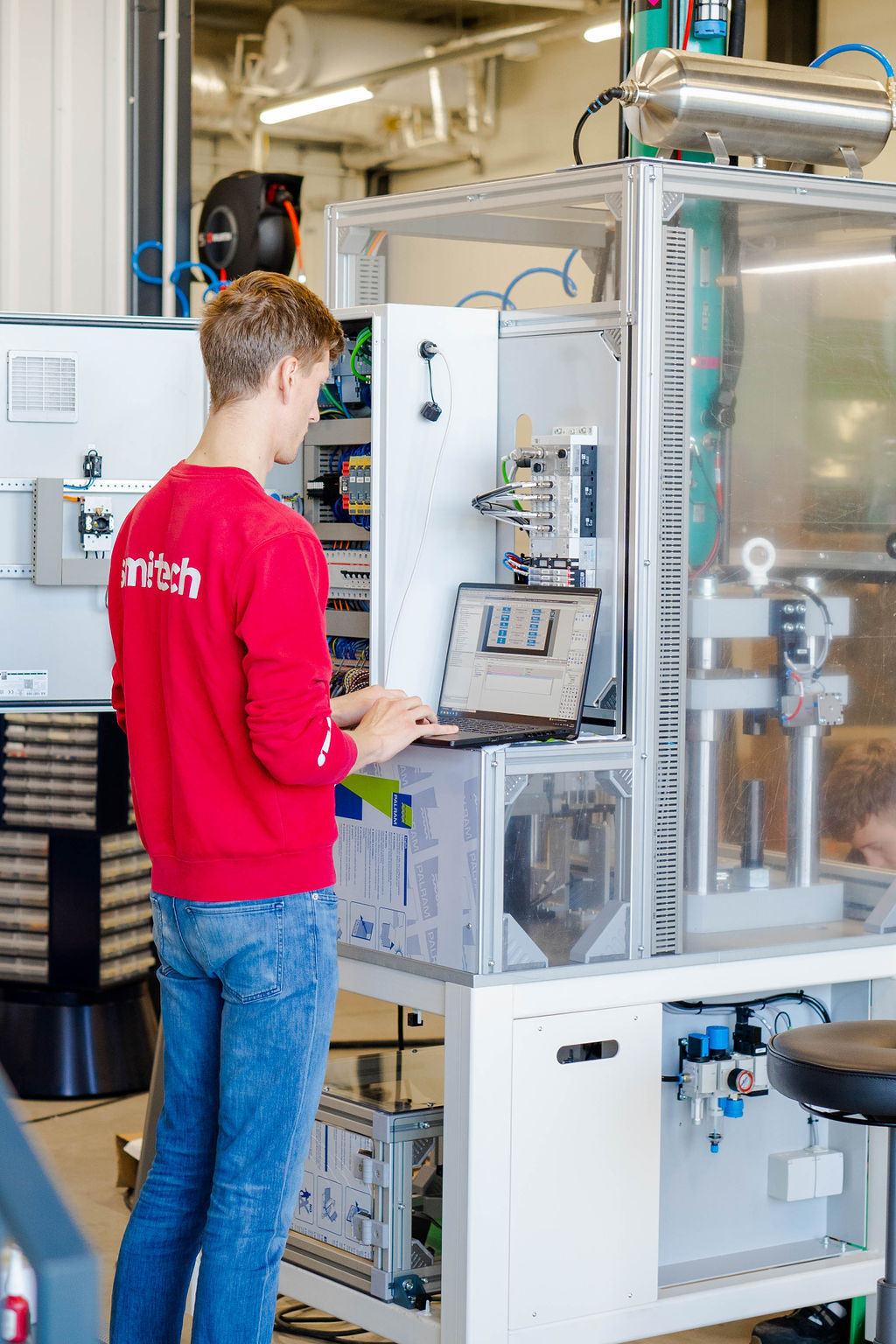

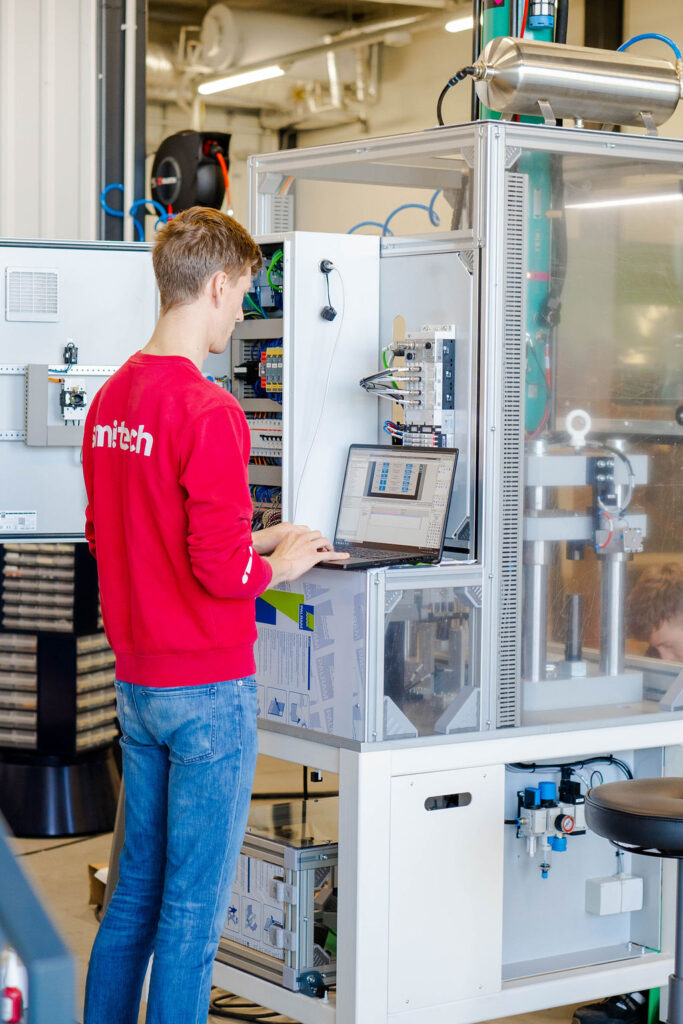

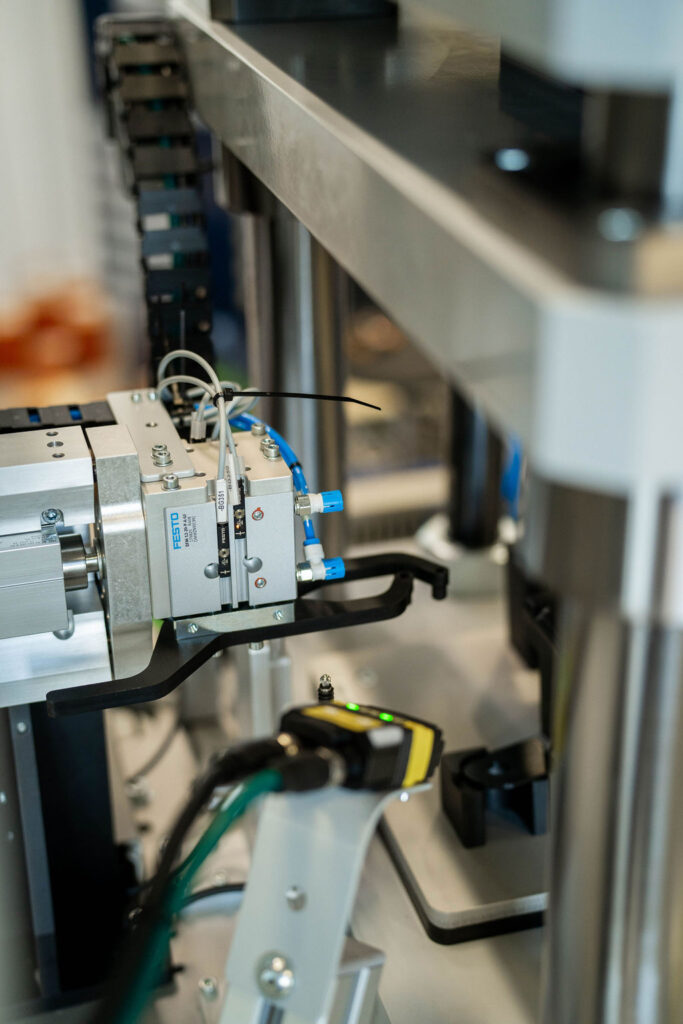

For AS Norma, we developed and manufactured a highly automated riveting workstation specifically tailored for steel rivets. The workstation will be integrated into an existing production line as a strategic addition to enhance productivity and quality.

Technical Specifications:

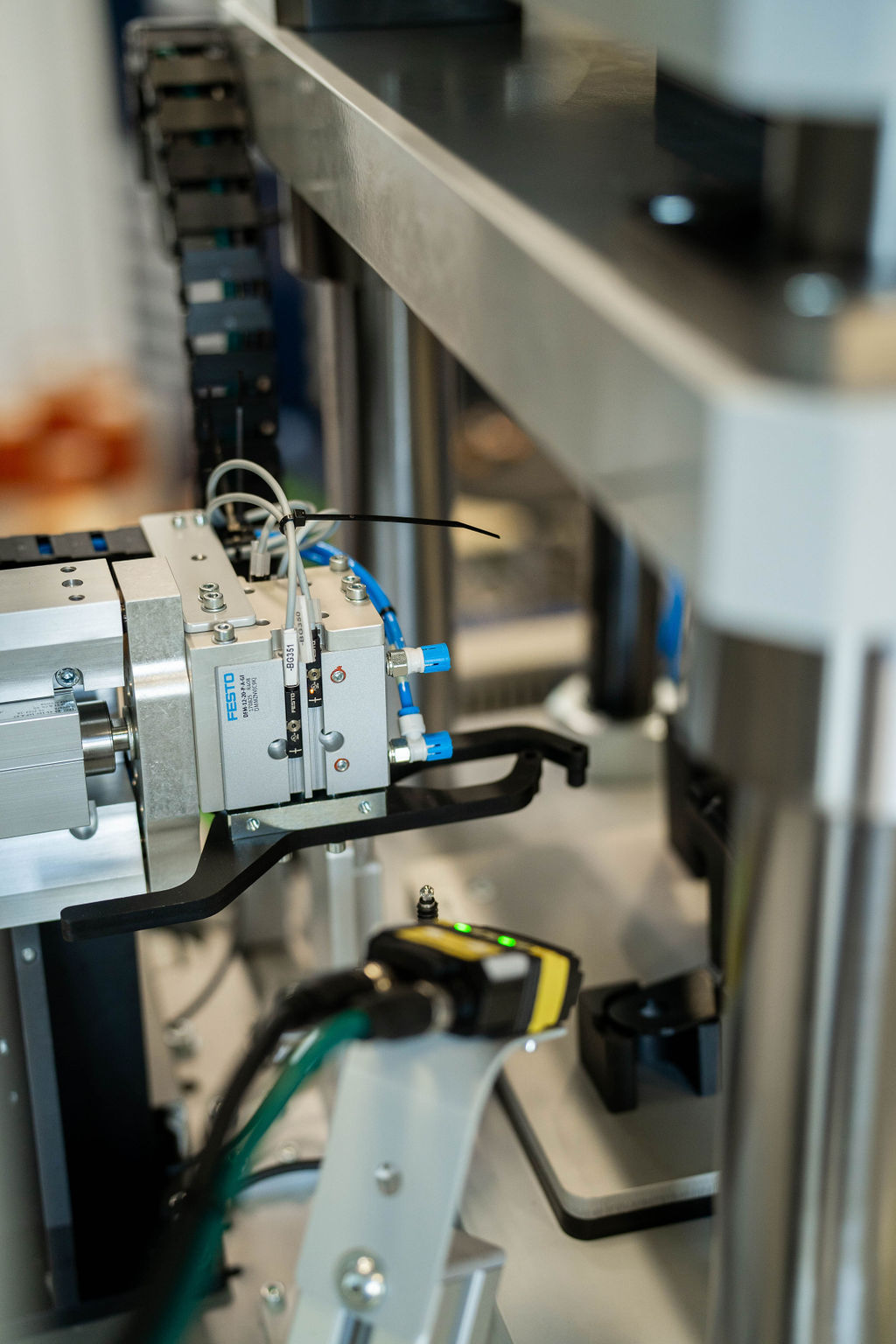

- Pressing Force: 30 tons, optimized for steel riveting

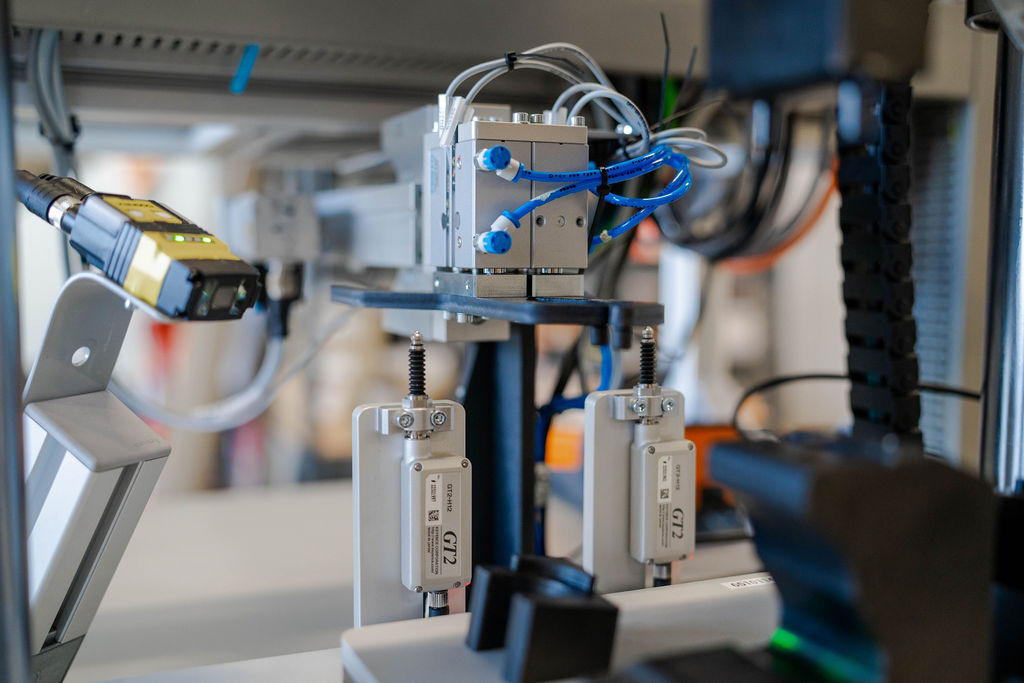

- Control System: 100% automated component and final assembly accuracy check using machine vision and scanners

- Precision: Riveting quality assured with a precision of +/- 0.05 mm

Functionalities:

- The system is modular, capable of manufacturing up to six different products

- A rapid cycle time of 13 seconds ensures high throughput

- The workstation is integrated into the existing production line to increase capacity

Project Components:

- Design and development of mechanical, electrical, and automation systems

- Safety systems design and installation

- PLC programming and camera configuration

- Machine production, testing, set-up at customer location

- CE certification, including risk analysis and conformity assessment

The workstation not only guarantees high-quality production but also increases productivity, making AS Norma’s manufacturing process even more efficient. Although there are no plans for additional developments at the moment, the system’s modularity offers the possibility for future expansion.